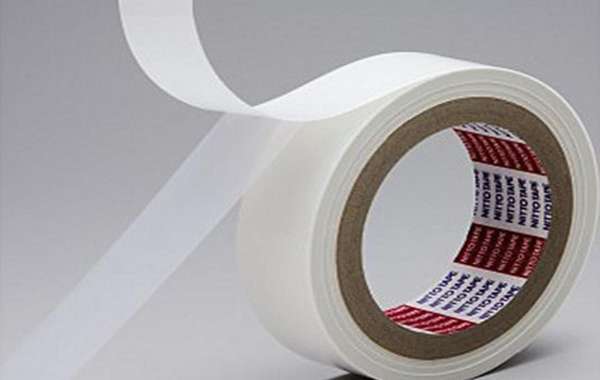

Double-sided adhesive tape has become an essential component in numerous industries, from automotive assembly to consumer electronics. Behind its widespread use lies a sophisticated manufacturing process driven by innovation and precision. This article explores the evolution of double-sided adhesive tape manufacturing, highlighting key innovations and diverse applications across industries.

The Manufacturing Process

Manufacturing double-sided adhesive tape involves a series of precise steps to ensure consistent quality and performance:

Substrate Selection: Manufacturers choose substrates such as paper, film, or foam based on the desired strength, flexibility, and application environment.

Adhesive Coating: A critical stage where adhesive layers are applied to both sides of the substrate. Different types of adhesives, including acrylics and rubber-based formulations, are used depending on the intended use case.

Curing and Drying: After coating, tapes undergo a curing process to set the adhesive and ensure proper bonding properties. This stage is crucial for achieving the desired strength and durability.

Slitting and Cutting: The coated rolls are slit into narrower widths and cut to specified lengths according to customer requirements. Precision in this stage is essential for efficient application and minimal waste.

Innovations Driving Industry Advancements

Advanced Adhesive Formulations: Manufacturers continually develop new adhesive formulations to improve performance characteristics such as temperature resistance, bonding strength, and repositionability.

Nano-technology: Integration of nanotechnology has enabled the development of ultra-thin tapes with exceptional bonding properties, suitable for delicate electronic components and medical devices.

Environmentally Friendly Solutions: Increasing emphasis on sustainability has led to the development of eco-friendly tapes using recyclable materials and solvent-free adhesives, reducing environmental impact.

Applications Across Industries

Double-sided adhesive tapes find extensive use in diverse industries:

- Automotive: Bonding interior trim, mounting emblems, and attaching weather seals.

- Electronics: Assembly of displays, circuit boards, and mobile devices where precision and reliability are crucial.

- Construction: Mounting mirrors, signage, and structural bonding in architectural applications.

- Healthcare: Medical tapes for wound care and surgical applications, offering gentle adhesion and hypoallergenic properties.

Quality Assurance and Standards

Manufacturers adhere to stringent quality standards to ensure reliability and safety in their products. Testing protocols include evaluating adhesive strength, temperature resistance, and aging characteristics to meet industry specifications and customer expectations.

Global Reach and Market Dynamics

The global market for double-sided adhesive tapes is expansive, with manufacturers catering to regional and international demands. Globalization has facilitated the exchange of technological know-how and market expansion, driving innovation and competitive pricing.

Future Trends and Challenges

Looking ahead, the industry is poised for further advancements driven by technological innovations and evolving customer needs. Key trends include:

- Smart Adhesive Technologies: Integration of sensors and responsive adhesives for adaptive applications.

- Industry 4.0: Adoption of digital manufacturing technologies for enhanced productivity and quality control.

- Regulatory Compliance: Adapting to changing regulations regarding materials and environmental impact.

Challenges such as raw material costs and supply double sided adhesive tape manufacturer remain pertinent, requiring manufacturers to adopt agile strategies and sustainable practices to mitigate risks.

Conclusion

In conclusion, double-sided adhesive tape manufacturing continues to evolve, driven by innovation, application diversity, and global demand. Manufacturers play a pivotal role in developing solutions that enhance product performance across industries while embracing sustainability and technological advancements.

By understanding these dynamics, stakeholders can navigate opportunities and challenges in this dynamic sector, ensuring continued growth and relevance in the global marketplace.