In the realm of modern infrastructure maintenance and rehabilitation, trenchless sewer repair technologies have emerged as revolutionary solutions. These advanced methods offer significant advantages over traditional excavation techniques by minimizing disruption, reducing costs, and improving overall efficiency. This comprehensive guide explores the various trenchless sewer repair technologies available today, their applications, benefits, and considerations.

Understanding Trenchless Sewer Repair

Trenchless sewer repair refers to a set of methods and technologies used to rehabilitate underground sewer pipelines without the need for extensive excavation. Traditional sewer repair typically involves digging trenches to access and replace damaged pipes, which can be disruptive, time-consuming, and costly. In contrast, trenchless methods allow for repairs to be conducted with minimal surface disruption, making them particularly advantageous in urban areas, densely populated neighborhoods, and environmentally sensitive locations.

Key Trenchless Sewer Repair Technologies

1. Pipe Relining (Cured-In-Place Pipe - CIPP)

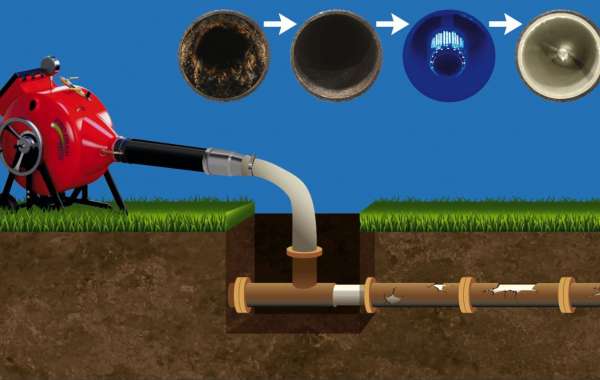

Trenchless sewer repair encompasses several key technologies, each with its specific applications and benefits. One of the most widely used methods is cured-in-place pipe (CIPP) lining. CIPP involves inserting a flexible liner coated with resin into the existing damaged pipe. The liner is then inflated and cured using heat or UV light, forming a new seamless pipe inside the old one. This method effectively seals leaks, restores structural integrity, and improves flow capacity without the need for excavation.

CIPP is suitable for a wide range of pipe materials, including clay, concrete, PVC, and cast iron, making it versatile for various sewer rehabilitation projects. Its seamless nature also reduces the risk of future root intrusion and corrosion, prolonging the lifespan of the rehabilitated pipeline.

2. Pipe Bursting

Pipe bursting is another trenchless technique used to replace old or damaged sewer pipes with new ones without the need for excavation. This method involves pulling a bursting head through the existing pipe, breaking it apart outward while simultaneously pulling in a new pipe of the same or larger diameter behind it. Pipe bursting is particularly beneficial for replacing deteriorated pipelines or upgrading sewer systems to accommodate increased capacity.

3. Slip Lining

Slip lining involves inserting a smaller diameter pipe (typically made of PVC or HDPE) into the existing damaged pipe. This method creates a new structural liner within the old pipe, effectively restoring flow capacity and improving hydraulic efficiency. Slip lining is often used for pipelines with moderate defects and is less disruptive than other trenchless methods, although it requires access points for insertion and extraction.

4. Microtunneling

Microtunneling combines trenchless technology with remote-controlled equipment to install new pipelines or conduct repairs beneath obstacles such as roads, railways, or rivers. This method utilizes a tunnel boring machine (TBM) to excavate and install pipelines simultaneously, minimizing surface disruption and environmental impact. Microtunneling is ideal for projects that require precise alignment and minimal disturbance to existing infrastructure.

Benefits of Trenchless Sewer Repair Technologies

1. Minimal Surface Disruption and Environmental Impact

One of the primary advantages of trenchless sewer repair technologies is their ability to minimize surface disruption and environmental impact. Unlike traditional excavation methods, which can involve extensive digging and disruption to landscapes, roads, and utilities, trenchless methods require only small access points. This reduces traffic disruptions, noise pollution, dust, and soil disturbance, preserving urban aesthetics and minimizing the project's environmental footprint.

2. Cost-Effectiveness

While initial costs for trenchless sewer repair technologies may be higher than traditional methods, they often result in overall cost savings. Factors such as reduced labor, shorter project durations, lower material costs, and minimized restoration expenses contribute to cost-effectiveness. Additionally, trenchless methods eliminate the need for extensive surface restoration and traffic management, further reducing project costs and logistical challenges.

3. Faster Project Completion

Trenchless sewer repair technologies typically result in faster project completion times compared to traditional excavation methods. The streamlined process, reduced dependency on weather conditions, and minimal disruption to daily activities allow for quicker turnaround times. This is particularly advantageous in urban areas where minimizing disruption to businesses, residents, and traffic flow is crucial.

4. Long-Term Durability and Reliability

The rehabilitated pipelines using trenchless methods often exhibit enhanced durability and reliability. Technologies such as CIPP create seamless, corrosion-resistant liners that improve hydraulic performance and reduce the likelihood of future leaks, cracks, or root intrusion. This extended service life minimizes the need for frequent maintenance and repair, contributing to long-term cost savings and sustainable infrastructure management.

Considerations and Challenges

While trenchless sewer repair technologies offer numerous benefits, they are not without considerations and challenges:

Technical Expertise: Proper assessment, design, and execution require specialized knowledge and expertise in trenchless technologies.

Site Conditions: Access points, soil conditions, and pipe material compatibility are critical factors that influence the feasibility and success of trenchless methods.

Regulatory Compliance: Adherence to local regulations, permits, and environmental standards is essential to ensure the safe and lawful execution of trenchless sewer repair projects.

Conclusion

Trenchless sewer repair technologies have revolutionized the way underground infrastructure is rehabilitated and maintained. From minimizing surface disruption and environmental impact to improving cost-effectiveness, efficiency, and long-term durability, these methods offer significant advantages over traditional excavation techniques. As municipalities, utilities, and engineers continue to prioritize sustainable and efficient infrastructure solutions, the adoption of trenchless sewer repair technologies is expected to grow, paving the way for a more resilient and environmentally responsible approach to infrastructure management.