In the world of construction and civil engineering, high-density polyethylene (HDPE) has become a staple material due to its durability, chemical resistance, and versatility. Among its various forms, HDPE T rib liner sheets are particularly noteworthy for their unique structural features and applications. This article will explore what HDPE T rib liner sheets are, their benefits, uses, and important factors to consider when selecting an HDPE T rib liner manufacturer.

What are HDPE T Rib Liner Sheets?

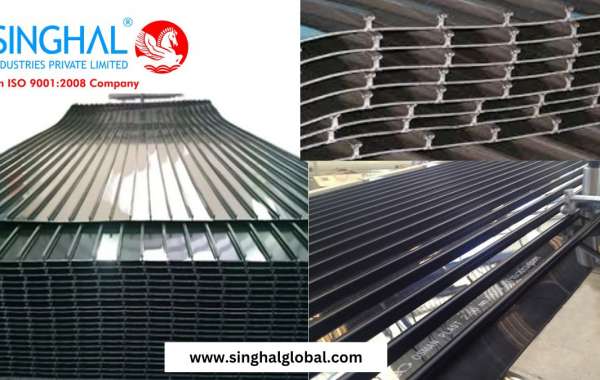

HDPE T rib liner sheets are specialized sheets made from high-density polyethylene that feature a ribbed design. This unique T-shaped ribbing provides enhanced strength and rigidity, making these sheets suitable for a wide range of applications. The design allows for improved load distribution and adds to the overall structural integrity of the sheets. HDPE T rib liner sheets are commonly used in environments where durability and resistance to harsh conditions are essential.

Key Features of HDPE T Rib Liner Sheets

Enhanced Strength: The ribbed design of HDPE T rib liner sheets increases their tensile strength, making them ideal for applications that require robust materials.

Chemical Resistance: HDPE is inherently resistant to a wide variety of chemicals, making these liners suitable for use in chemical storage and transport applications.

Lightweight and Easy to Handle: Despite their strength, HDPE T rib liner sheets are lightweight, facilitating easy handling and installation.

Water Resistance: These sheets are impervious to water, making them ideal for applications in wet environments or where water exposure is likely.

Cost-Effective: The longevity and durability of HDPE materials mean that they can be a cost-effective solution over time, reducing the need for frequent replacements.

Benefits of Using HDPE T Rib Liner Sheets

Using HDPE T rib liner sheets offers numerous advantages, including:

Versatility: These sheets can be used in a variety of applications, including retaining walls, pond liners, and as protective liners in industrial settings.

Ease of Installation: The lightweight nature of the sheets makes them easy to transport and install, reducing labor costs and project timelines.

Resistance to UV Radiation: HDPE T rib liner sheets can withstand prolonged exposure to sunlight without degrading, making them suitable for outdoor applications.

Environmental Impact: HDPE is a recyclable material, making these liners an environmentally friendly choice compared to other plastics.

Low Maintenance: The durability and water resistance of HDPE T rib liner sheets mean that they require minimal maintenance, making them a practical option for long-term use.

Applications of HDPE T Rib Liner Sheets

HDPE T rib liner sheets are utilized across various industries due to their unique properties:

- Agriculture: Used as liners in irrigation canals and ponds to prevent water loss and contamination.

- Construction: Employed as protective barriers in retaining walls and foundation linings, enhancing structural integrity.

- Waste Management: Commonly used in landfill liners to prevent leachate migration and protect the environment.

- Mining: Used as liners in tailings ponds, providing a durable barrier against hazardous materials.

- Industrial: Employed in chemical storage facilities, offering protection against spills and leaks.

Choosing the Right HDPE T Rib Liner Manufacturer

Selecting a reliable HDPE T rib liner manufacturer is critical to ensure the quality and performance of the product. Here are some important factors to consider:

Reputation: Look for manufacturers with a strong track record in the industry. Customer reviews and testimonials can provide insights into their reliability.

Quality Standards: Ensure the manufacturer adheres to relevant industry standards and certifications. This guarantees that their products meet the necessary quality and safety requirements.

Product Range: A good manufacturer should offer a variety of HDPE T rib liner sheets in different sizes and thicknesses to meet diverse project needs.

Customer Support: Assess the level of customer service provided. A responsive manufacturer can assist with technical inquiries and offer support during installation.

Customization Options: Some projects may require specific features or custom sizes. A flexible manufacturer can accommodate these needs.

FAQs

1. How are HDPE T rib liner sheets installed?

Installation typically involves preparing the site, laying the sheets in the desired configuration, and securing them in place. Depending on the application, additional measures like anchoring or welding may be required.

2. Can HDPE T rib liner sheets be used in extreme temperatures?

Yes, HDPE T rib liner sheets are designed to withstand a wide range of temperatures, making them suitable for both hot and cold climates.

3. Are HDPE T rib liner sheets environmentally friendly?

Absolutely! HDPE is a recyclable material, and the longevity and durability of these sheets contribute to their sustainability. They can reduce the need for frequent replacements, minimizing waste.