Geomembranes have emerged as crucial components in construction, environmental engineering, and various industrial projects. Known for their impermeable properties, geomembranes offer reliable solutions to contain, protect, and separate Pulkit Plastic Products different environments, helping to prevent the contamination of soil, water, and other natural resources. In this comprehensive guide, we’ll delve into what geomembranes are, their types, applications, benefits, and address common questions about their use.

What is Geomembrane?

Geomembrane refers to a type of synthetic membrane liner or barrier that is used to control the migration of fluids or gases in projects ranging from landfills and mining operations to water reservoirs and agricultural ponds. These liners are typically made from polymers like high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyvinyl chloride (PVC), or ethylene propylene diene monomer (EPDM).

Key Properties of Geomembranes

- Impermeability: Geomembranes are primarily designed to be impermeable, preventing the passage of liquids and gases through the material.

- Durability: They are designed to withstand harsh environmental conditions, including ultraviolet (UV) exposure, chemical reactions, and physical damage.

- Flexibility: Depending on the specific polymer used, geomembranes offer flexibility to accommodate different ground movements without cracking or tearing.

Types of Geomembrane Materials

Choosing the right geomembrane depends on the application and the properties needed. Here are the most common types:

1. High-Density Polyethylene (HDPE) Geomembrane

HDPE geomembranes are widely used because of their excellent chemical resistance and cost-effectiveness. They are commonly applied in waste containment, landfills, and water conservation projects. HDPE geomembranes are durable and have a high puncture resistance, making them suitable for harsh environments.

2. Low-Density Polyethylene (LDPE) Geomembrane

LDPE Geomembrane manufacturers in india are more flexible compared to HDPE. They are often preferred in projects that require a material that can adapt to irregular surfaces, such as pond liners or water reservoirs. However, they offer slightly less chemical resistance compared to HDPE.

3. Polyvinyl Chloride (PVC) Geomembrane

PVC geomembranes are known for their flexibility and ease of installation. They are commonly used in short-term projects or in environments where flexibility is critical. However, they are more susceptible to UV degradation and require protection if exposed to sunlight for long periods.

4. Ethylene Propylene Diene Monomer (EPDM) Geomembrane

EPDM is a synthetic rubber material known for its elasticity and resistance to weathering. It is widely used in ponds, reservoirs, and water containment applications. EPDM geomembranes have superior resistance to UV exposure and extreme temperatures, making them ideal for outdoor use.

Applications of Geomembranes

Geomembranes serve as critical components in a wide array of applications. Here are some common uses:

1. Landfill Liners and Covers

Geomembranes are extensively used in landfills to prevent the leakage of hazardous waste into the surrounding soil and groundwater. They act as a barrier to contain leachate, protecting the environment from contamination.

2. Mining Operations

In mining, geomembranes are used to line heap leach pads and tailings dams, ensuring that toxic substances do not infiltrate the surrounding area. Their chemical resistance makes them suitable for these applications.

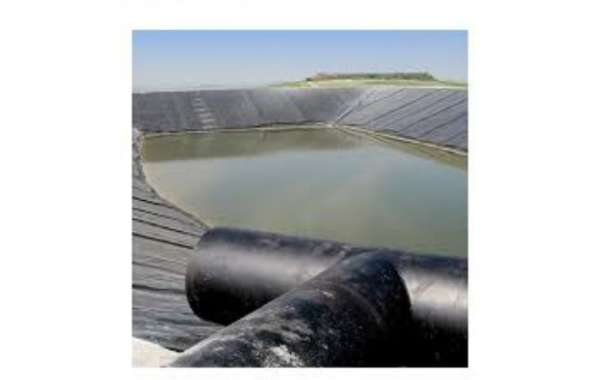

3. Water Reservoirs and Ponds

Water conservation is a critical concern, and Geomembrane Sheets in India provide a practical solution for lining reservoirs, ponds, and canals. By preventing seepage, they help retain water, which is especially vital in arid regions.

4. Agricultural Applications

In agriculture, geomembranes are used for lining irrigation canals, waste storage lagoons, and aquaculture ponds. They help maintain water quality and manage waste efficiently.

5. Tunnel and Dam Construction

Geomembranes are used as waterproofing membranes in tunnel and dam construction to control seepage and protect the structural integrity of these projects.

Benefits of Using Geomembrane

- Environmental Protection: Geomembranes play a vital role in environmental conservation by preventing pollutants from seeping into the soil and water.

- Cost-Effective: Compared to traditional methods of seepage control, geomembranes are cost-effective and efficient in the long run.

- Ease of Installation: With advances in material technology, geomembranes are relatively easy to install, reducing the labor and time needed for project completion.

- Durability and Low Maintenance: Once installed, geomembranes require minimal maintenance and can last for decades, offering long-term solutions for various containment needs.

Factors to Consider When Choosing a Geomembrane

1. Project Requirements

Assess the specific needs of your project. For example, if chemical resistance is a priority, HDPE geomembrane would be a suitable choice.

2. Environmental Conditions

Consider factors like UV exposure, temperature fluctuations, and chemical interactions that could impact the geomembrane’s performance.

3. Thickness and Flexibility

The thickness of a geomembrane affects its strength and flexibility. A thicker geomembrane is ideal for high-impact applications, while a thinner, more flexible material may be needed for irregular surfaces.

4. Cost Implications

Budget constraints can influence the choice of material. However, it’s crucial to balance cost with performance and longevity to ensure optimal results.

Conclusion

Geomembranes are indispensable in a variety of industries, offering reliable and durable solutions for containment, environmental protection, and water conservation. By understanding the types, applications, and benefits of HDPE Geomembrane , engineers and project managers can make informed decisions to optimize performance and sustainability in their projects.

Frequently Asked Questions (FAQs)

1. What is the lifespan of a geomembrane?

The lifespan of a geomembrane depends on the material and the environmental conditions it is exposed to. HDPE geomembranes, for instance, can last over 30 years when properly installed and maintained. Factors like UV exposure, chemical contact, and physical stress can impact their longevity.

2. How is geomembrane installed?

Geomembrane installation involves several steps, including site preparation, deploying the material, seaming the panels together, and conducting quality assurance tests. The process may vary depending on the specific application and material used.

3. Can geomembranes be recycled?

Yes, many geomembrane materials, such as HDPE and PVC, are recyclable. Recycling practices vary by region and depend on the availability of facilities that can handle synthetic polymer recycling.

4. What is the difference between HDPE and LDPE geomembranes?

HDPE geomembranes are more rigid and have higher chemical resistance, making them suitable for demanding environments like landfills. LDPE geomembranes, on the other hand, are more flexible and easier to work with, making them ideal for applications requiring adaptability to uneven surfaces.