Additive engineering solutions, often synonymous with 3D printing, have transformed the manufacturing landscape across industries. By offering unparalleled flexibility, reduced waste, and accelerated production, this innovative technology has enabled businesses to achieve breakthroughs in design and production. From aerospace to healthcare, additive engineering is driving advancements that were once unimaginable.

In this article, we’ll explore five key industries leveraging additive engineering solutions and how they are reaping the benefits.

What Are Additive Engineering Solutions?

Additive engineering involves creating objects layer by layer from digital designs, bypassing the need for extensive tooling or subtractive methods. This precision-driven approach allows for the production of complex geometries, lightweight components, and customized solutions with minimal waste.

To delve deeper into the materials that make additive manufacturing possible, check out this detailed guide on additive engineering solutions.

1. Aerospace: Lightweight and High-Performance Components

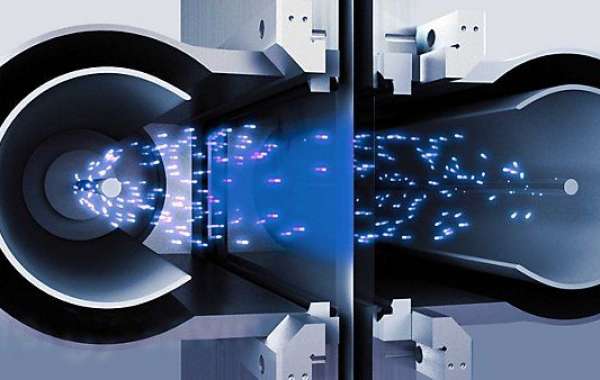

The aerospace industry was among the first to embrace additive engineering solutions. Precision, durability, and weight reduction are critical in aerospace applications, and additive engineering delivers on all fronts.

- Lightweight Design: Additive engineering enables the creation of intricate, lightweight components that reduce fuel consumption and enhance aircraft performance.

- Part Consolidation: Multiple components can be combined into a single part, simplifying assembly and improving reliability.

- Customization: Additive manufacturing supports the production of specialized components for aircraft maintenance and upgrades.

Notable Example: Aircraft engine manufacturers now use additive engineering to produce turbine blades with improved heat resistance and aerodynamic efficiency.

2. Healthcare: Personalized and Efficient Solutions

Additive engineering has revolutionized the healthcare sector, offering customized medical devices and improved patient outcomes.

- Customized Prosthetics and Implants: Additive engineering enables the production of prosthetics and implants tailored to individual patients, improving comfort and functionality.

- Surgical Guides: Surgeons use 3D-printed guides for precision operations, enhancing the success rate of complex procedures.

- Bioprinting: Emerging applications include printing tissues and organs for medical research and future transplants.

Notable Example: Dentists now use 3D printing for creating crowns, bridges, and aligners that perfectly match a patient’s unique anatomy.

3. Automotive: Prototyping and Production Redefined

The automotive industry uses additive engineering for both prototyping and manufacturing end-use parts.

- Rapid Prototyping: Engineers can design, test, and refine vehicle components quickly, reducing development cycles.

- Lightweight Parts: Additive engineering supports the creation of lightweight, high-strength parts that improve fuel efficiency.

- Spare Parts Production: On-demand production of spare parts eliminates inventory issues and reduces downtime.

Notable Example: Formula 1 teams use additive engineering to produce aerodynamic components that give them a competitive edge on the track.

4. Consumer Goods: Mass Customization at Scale

In the consumer goods sector, the demand for personalized products is on the rise. Additive engineering makes it possible to produce unique designs at scale.

- Personalized Products: Companies can offer tailored solutions, from custom-fit footwear to bespoke home décor items.

- Eco-Friendly Designs: Additive engineering supports sustainable practices by using biodegradable materials and reducing waste.

- Niche Markets: Small batch production becomes feasible, allowing companies to cater to specialized audiences.

Notable Example: Jewelry brands use additive engineering to produce intricate designs that are otherwise impossible to create with traditional methods.

5. Construction: Innovative Building Techniques

The construction industry has begun to adopt additive engineering for creating complex structures and reducing material waste.

- 3D-Printed Buildings: Entire structures can now be printed using large-scale additive manufacturing equipment, cutting down construction time and labor costs.

- Sustainable Practices: Additive engineering minimizes waste by precisely depositing materials where needed.

- Complex Designs: Architects can bring intricate, futuristic designs to life with additive manufacturing techniques.

Notable Example: Companies are using concrete 3D printing to build affordable housing in record time, addressing the global housing crisis.

Challenges and Opportunities Across Industries

While additive engineering solutions have transformed these industries, they are not without challenges:

- Material Limitations: The range of materials available for additive manufacturing is expanding but remains a constraint for some applications.

- Cost: Initial investment in equipment and training can be high, particularly for small businesses.

- Scalability: While suitable for small-scale production, additive manufacturing needs further advancements to compete with traditional mass production methods.

Nevertheless, innovations in material science and process efficiency are rapidly addressing these challenges, paving the way for wider adoption.

The Future of Additive Engineering Solutions

The integration of additive engineering with technologies like artificial intelligence (AI) and the Internet of Things (IoT) will further enhance its capabilities. From smarter design optimization to real-time monitoring, these advancements will unlock new opportunities across industries.

Additionally, the development of sustainable materials and energy-efficient machines will solidify additive manufacturing’s role in creating a greener future.

Conclusion

Additive engineering solutions are revolutionizing industries by offering innovative, efficient, and sustainable approaches to manufacturing. From aerospace and healthcare to automotive and construction, the potential of this technology is vast and continually expanding.

If you’re exploring additive manufacturing for your business, understanding the materials available is a critical step. Learn more about the materials used in this transformative process by visiting this guide on additive engineering solutions.

As industries continue to innovate, additive engineering will remain at the forefront of modern manufacturing, driving advancements that shape the future. Whether you’re looking to enhance production efficiency, reduce waste, or meet the demands of customization, additive engineering solutions offer unparalleled possibilities.